processing range 20mm dia -200mm dia

max idling speed 80m/min

max accelerated 1.2g

xy positioning speed +-0.03mm

xy repeated positioning accuracy +-0.02mm

power supply 380v 50hz

laser power 500w-2000w

machine gross power below 25kva

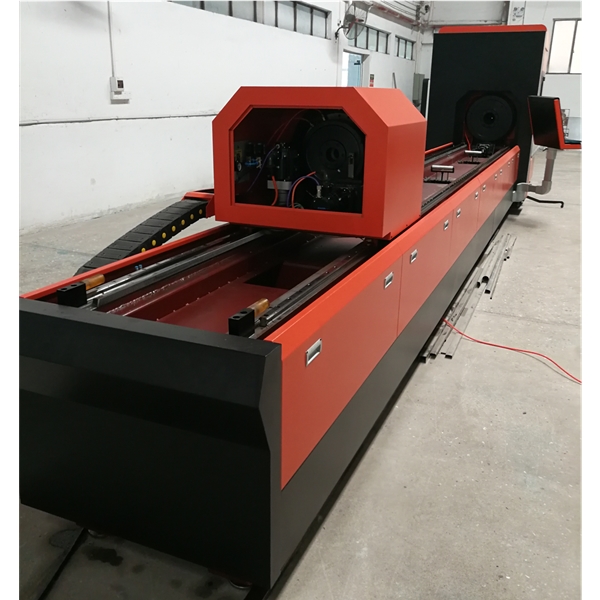

whole machine weight 5500kg

machine dimensions 700mm*4000mm*1700mm

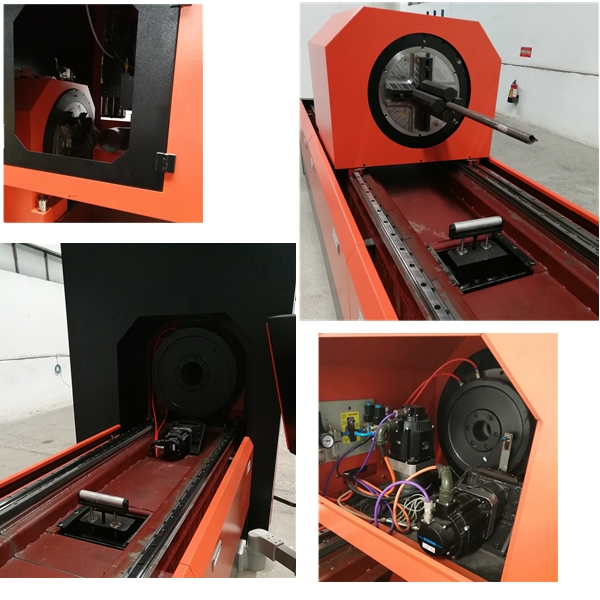

transmission precise pinion and rack, dual drive transmitting

adopting cyp tube cutting software, it can directly displayed the drawings

from 3-dimension drawing software and 2-dimension drawing software

which is more convinient and direct

the machine is equipped with different professional clamps, which will

ensure precise processing for pipes of different shapes and different dimension

unique holding and scratching design enables fast adjustment of different

pipes, thus high precision products can be made during processing.

It is also very necessary to choose a processing device that can both

cut and punch. In order to further increase the efficiency of steel pipe

production in the fencing industry, improve the quality of processing,

and reduce material waste, laser cutting machines for pipes have

become the winning “weapons” for various metal pipe manufacturers.

★ Convenience

Laser cutting does not require the production of molds, any cutting

shape is programmed by software, and end-users can control short

or medium production without creating a large number of templates.

People operating machine, machine work, the operation is simple

and convenient.

★Flexibility

Pipe laser cutting machine is almost “all-powerful.” It can process

any regular tube shape that has been programmed, and the laser

can cut perfectly in any direction. The shape of the template is

programmed by computer and can be quickly changed to provide

customers with personalized processing. Even at the last minute,

the operator can modify the design plan without affecting the

entire production process.

★ Accuracy

Laser processing can compensate for inaccuracies in post-print

processing. For example, the material may be stretched and

deformed, and the laser can be adjusted according to these

deformations. The conventional template production method

cannot.

Can cut a plurality of different directions and different diameters

of cylindrical intersecting line holes in the main pipe, and meet

the conditions of vertical and non-eccentric intersection between

the branch pipe axis and the main pipe axis.

Can cut the intersection point of the cylindrical intersecting

line at the end of the branch pipe to meet the condition of

perpendicular and oblique intersection of the eccentric

and non-eccentricity of the branch pipe axis and the main axis.

Can cut oblique end faces at the ends of round tubes.

Can cut the intersecting end of the branch pipe intersecting

with the circular main pipe.

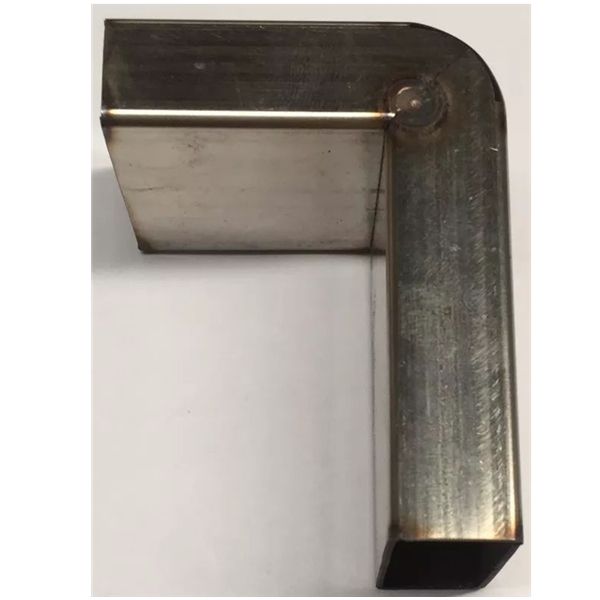

.Square tube cutting and 360° flip cutting can be performed.

.Can cut square holes and waist holes on round tubes.

Can cut off various steel pipes.

.Can be in the square tube, oval tube, U-tube, rectangular tube

surface and other special-shaped tube for a variety of graphic cutting.

Features:

Equipped with professional cutting control system, simple

layout can be realized.

Automatic corner energy at the corner of cutting square tube,

cutting speed, to achieve a satisfactory cutting effect.

Manually centered, professional tooling fixture design, peer

craftsmanship in a leading position to ensure cutting effect

Tubes such as round tubes and rectangular tubes can be fed

fully automatically without manual intervention; special shaped

tubes can be manually assisted with semi-automatic feeding.

Advanced chuck mounting system.

The chuck self-adjusts the center and automatically adjusts

the clamping force according to the profile specifications to

ensure that the thin tube is clamped without damage.

Corner quick cutting system.

The corners respond quickly and greatly improve cutting efficiency.

There are no reviews yet.